Understanding the Regulations and Standards for Disposable Gloves

In environments where hygiene and safety are paramount, the use of disposable gloves is ubiquitous. Whether in healthcare, food service, or industrial settings, the quality and effectiveness of these gloves are critical. To ensure a standard level of protection, various regulations and standards govern the manufacturing and use of disposable gloves. Let’s explore the key regulations and standards that play a crucial role in defining the quality and safety of disposable gloves.

Global Standards for Disposable Gloves

ASTM International: The American Society for Testing and Materials (ASTM) establishes standards for a wide range of products, including disposable gloves. ASTM D6319 outlines the specifications for nitrile, latex, and vinyl examination gloves, covering dimensions, physical properties, and performance testing.

International Organization for Standardization (ISO): ISO standards play a global role in ensuring the quality and safety of various products. ISO 11193 outlines requirements for single-use rubber gloves, covering aspects such as size designation, dimensions, and physical properties.

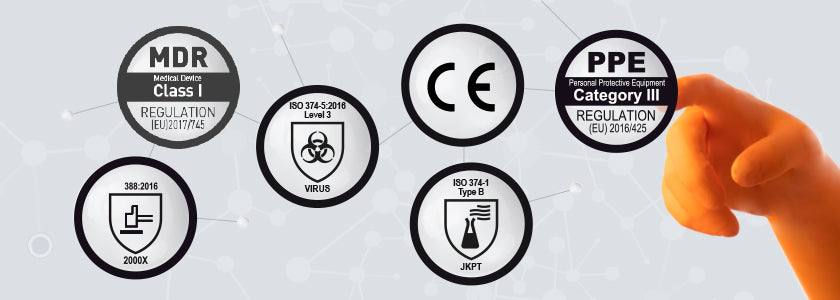

European Norm (EN): In Europe, disposable gloves must adhere to the EN standards. EN 455 specifies requirements for medical gloves to ensure their safety and performance. Additionally, EN 374 focuses on gloves designed to protect against chemicals and microorganisms.

Regulations in the United States

Food and Drug Administration (FDA): The FDA regulates disposable gloves in the United States. Medical gloves, including examination and surgical gloves, must meet the requirements outlined in FDA 510(k) premarket notifications. The FDA also provides guidance on labeling and performance testing.

Occupational Safety and Health Administration (OSHA): OSHA sets guidelines for the use of personal protective equipment (PPE), including gloves, in workplaces. Employers are required to assess the workplace for hazards and provide appropriate PPE, including gloves, based on OSHA standards.

Considerations in Selecting Gloves

Glove Material: Different standards may apply to gloves made from various materials, such as nitrile, latex, or vinyl. Understanding the specific requirements for each material is essential in selecting the right gloves for a given application.

Intended Use: Regulations and standards often vary based on the intended use of gloves, whether they are for medical examinations, surgical procedures, or protection against specific hazards like chemicals. Always match the glove's intended use with the applicable standards.

Performance Testing: Look for gloves that have undergone performance testing according to relevant standards. This ensures that the gloves meet specific criteria for dimensions, tensile strength, puncture resistance, and other critical factors.

Compliance Certification: Manufacturers often provide certification indicating compliance with relevant standards. Checking for certifications ensures that the gloves have undergone testing to meet specific safety and quality benchmarks.

Quality Management Systems: Some standards, such as ISO 13485, focus on quality management systems for medical device manufacturing. Manufacturers adhering to these standards demonstrate a commitment to quality and compliance throughout the production process.

Navigating the landscape of regulations and standards for disposable gloves is essential for ensuring the safety and efficacy of these critical protective tools. Whether in medical, food service, agricultural, industrial, or laboratory applications, understanding and adhering to the applicable standards is a fundamental step in promoting a culture of safety and compliance. By selecting gloves based on industry-specific requirements, organizations can confidently uphold the highest standards of protection and quality in their use of disposable gloves.

Leave a comment